Design exploration of historical structures as inspiration for 3D Concrete Printing (3DCP)

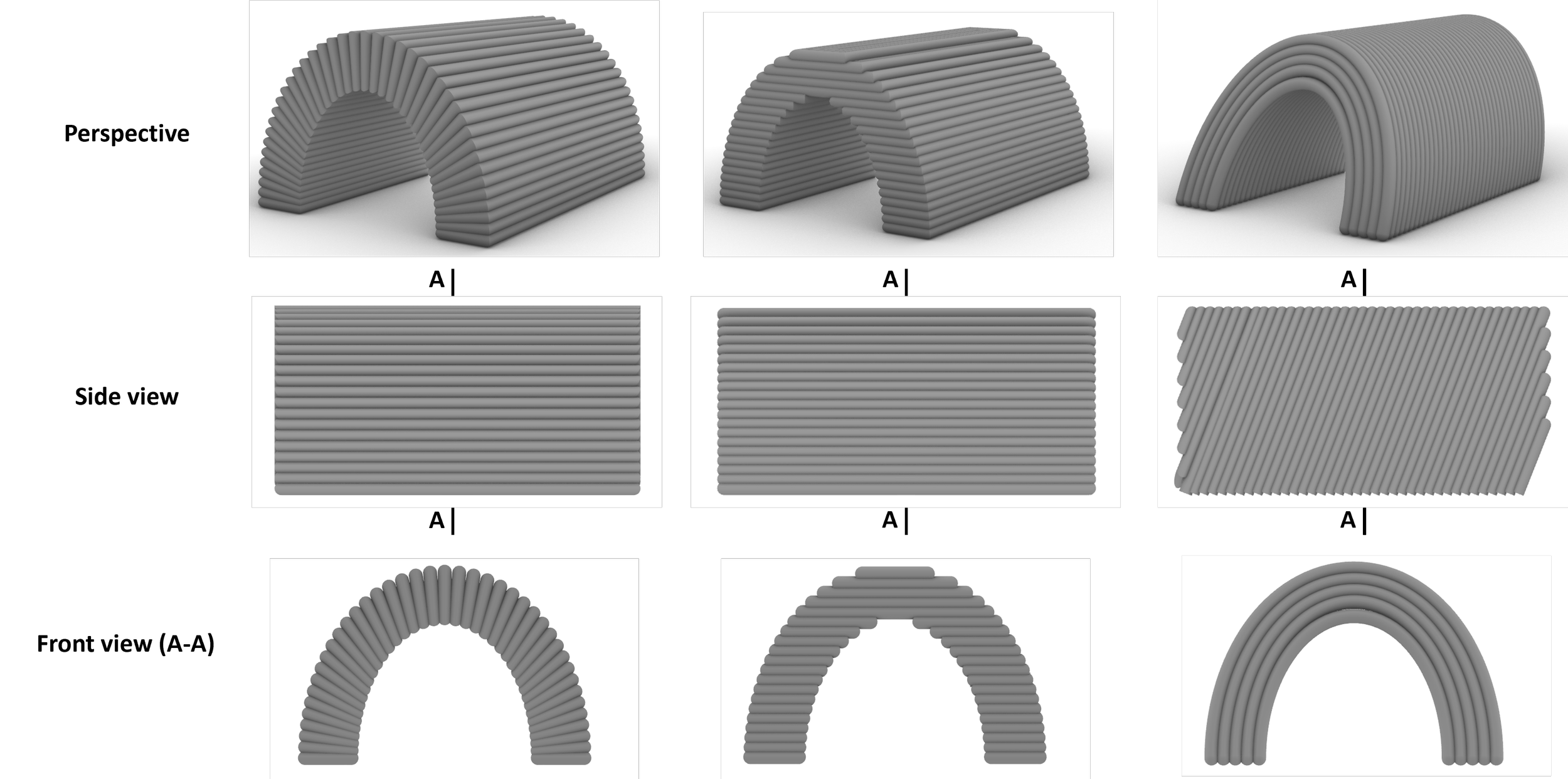

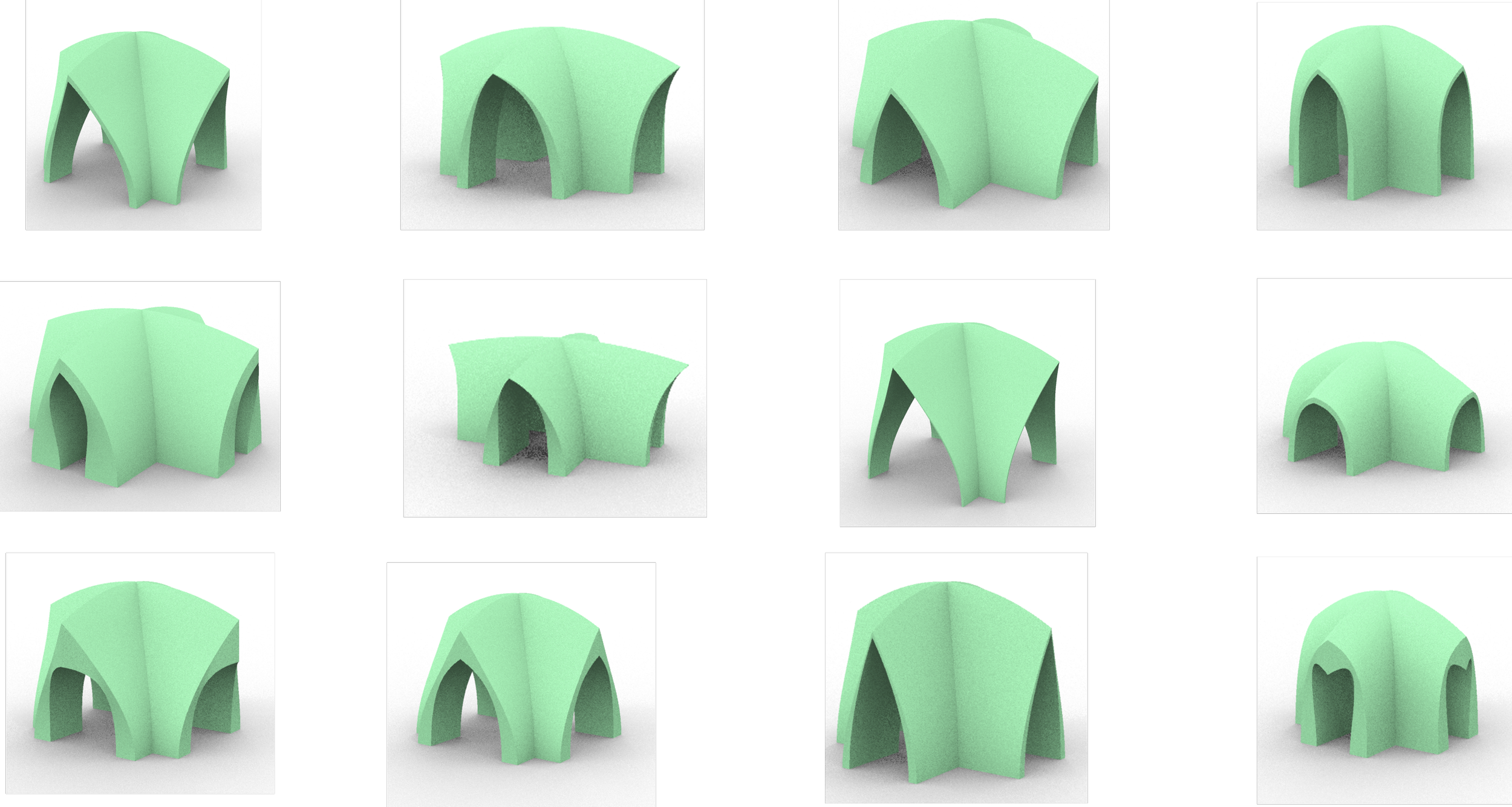

The compression-dominant behavior of unreinforced concrete demands architectural forms that efficiently propagate loads through compression. By studying historical structures that rely primarily on compression under deadloads such as arches, vaults, and domes—this research extracts lessons applicable to 3D concrete printing (3DCP).

The project identifies geometries whose structural principles align with 3DCP’s material behavior and fabrication constraints. Selected historic examples are analyzed in terms of their structural logic, materials, and construction techniques, focusing on how foundations, walls, and roofs were shaped to maintain stability without reinforcement or formwork.

Ultimately, insights from these compression-based structures inform new approaches for affordable, sustainable housing and emergency shelters using 3D-printed concrete that exploits geometry, rather than reinforcement, while eliminating the use of formwork.

Author:

Gonçalo Marques Duarte

Committee Members:

Jose Pinto Duarte, Ph.D.

Nathan Brown, Ph.D.

Ali Memari, Ph.D.